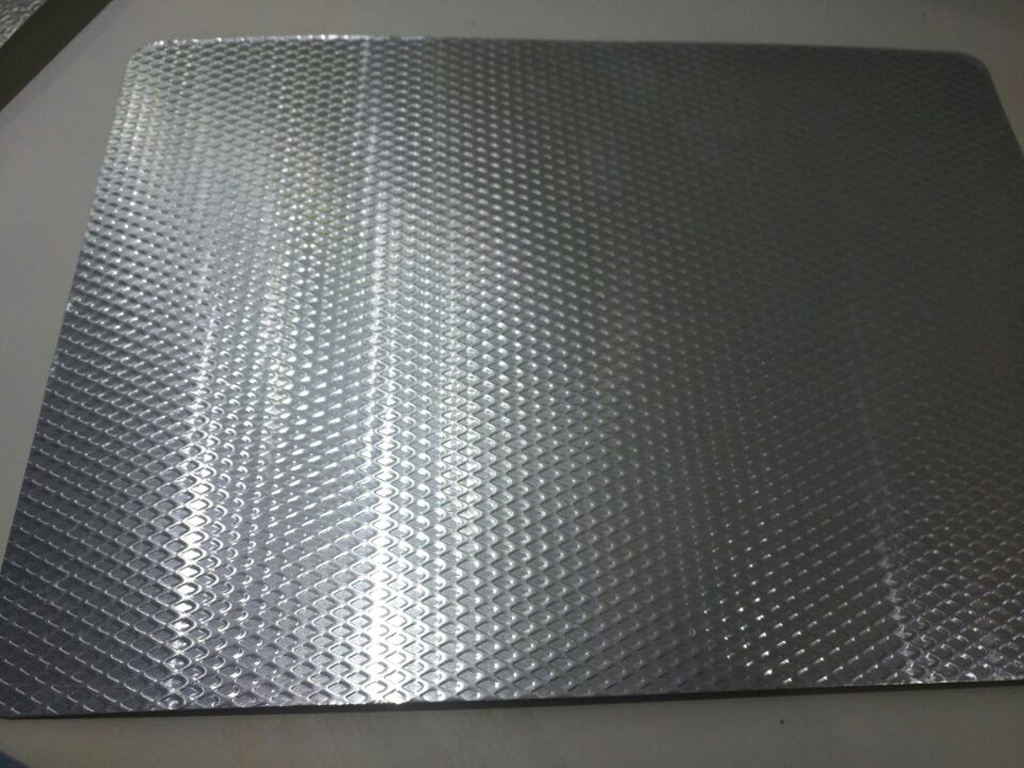

Color coated aluminum coil (for roof panels)

Category:

Color-coated aluminum coil, as the name suggests, is to color the surface coating of aluminum plate or (aluminum coil). The common ones are fluorocarbon color-coated aluminum coil and polyester color aluminum coil, which are widely used in aluminum-plastic panel, aluminum veneer, aluminum honeycomb panel, aluminum ceiling, roof surface, leftovers, cans, electronic products. Its performance is very stable and not easy to be corroded.

Keywords:

E-mail:

Details

Color-coated aluminum coil, as the name suggests, is to color the surface coating of aluminum plate or (aluminum coil). The common ones are fluorocarbon color-coated aluminum coil and polyester color aluminum coil, which are widely used in aluminum-plastic panel, aluminum veneer, aluminum honeycomb panel, aluminum ceiling, roof surface, leftovers, cans, electronic products. Its performance is very stable and not easy to be corroded.

characteristic

1. Flatness: There is no compound high temperature indentation on the surface, and there is no residual stress on the board surface.

2. Decorative: painted with wood grain and stone grain, with realistic physical texture and fresh natural beauty.

3. Weather resistance: The paint pattern made by coating and high temperature baking has high gloss retention, good color stability and small color difference changes.

4. Mechanical properties: high-quality aluminum, plastic and adhesives are selected, and advanced compounding technology is adopted.

5. Environmental protection: It is resistant to salt-alkali acid rain corrosion, it will not corrode and produce toxic bacteria, does not release toxic gases, does not cause corrosion of keels and fixtures, and is flame retardant.

Aluminum Magnesium Manganese Roof Panel

Light weight The density of aluminum is 2.73G/M3, only 1/3 of steel

Fluorocarbon Aluminum Magnesium Manganese 25-430

Light weight The density of aluminum is 2.73G/M3, only 1/3 of steel

65-400 Aluminum Magnesium Manganese

Light weight The density of aluminum is 2.73G/M3, only 1/3 of steel

65-430 Aluminum Magnesium Manganese

It has many advantages such as corrosion resistance, beauty, light weight, high strength, easy processing and molding. It is widely used in airport terminals, aircraft maintenance depots, stations and large transportation hubs, conference and exhibition centers, stadiums, exhibition halls, large public entertainment facilities, public service buildings, large shopping malls, commercial facilities, civil residences and other buildings. The 270 ° occlusion process of this roof panel is made by automatic professional operation of the automatic occlusion machine to bite the bilateral single support, and the package buckling method formed by the buckling edge and the support ingeniously solves the physical displacement caused by thermal expansion and contraction. This advantage is reflected in the fact that the lengthwise long-span roofing system does not deform due to internal and external forces. At the same time, the complete and complete supply of accessories for this roofing system can meet the requirements of various building forms.

Leave A Message