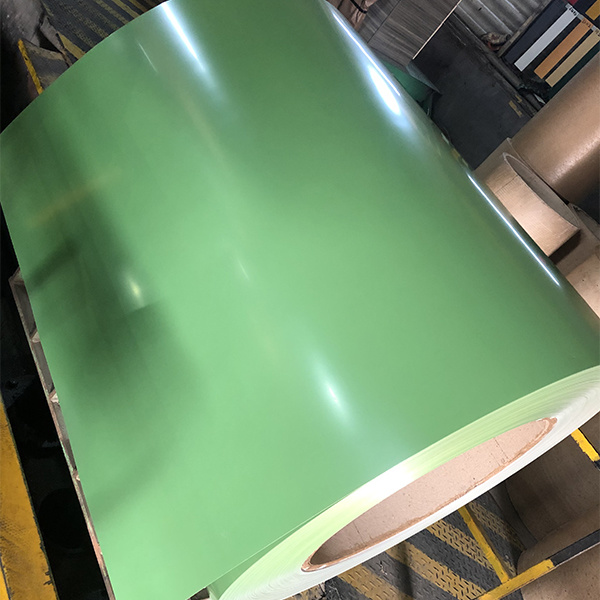

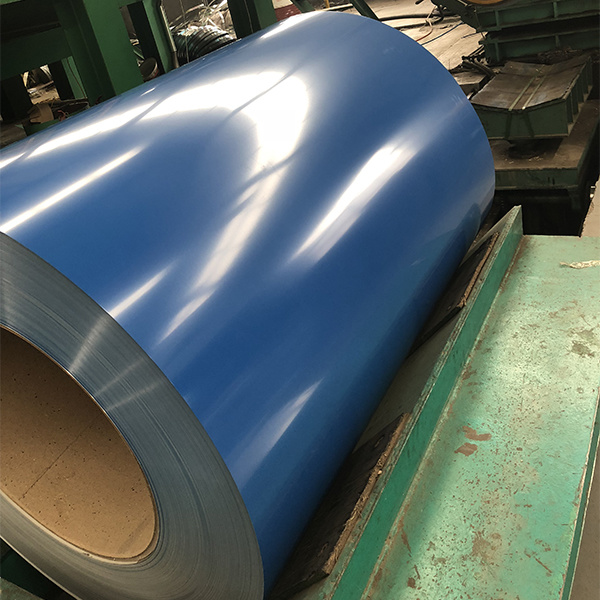

Stainless steel color coated plate

Category:

Stainless steel color-coated sheet has the characteristics of high anti-corrosion and high strength, and can be widely used in public buildings such as airports, stations, stadiums, power plants, chemical industry, coastal, solar energy and other application fields with high anti-corrosion requirements.

Keywords:

E-mail:

Details

Stainless steel color-coated sheet has the characteristics of high anti-corrosion and high strength, and can be widely used in public buildings such as airports, stations, stadiums, power plants, chemical industry, coastal, solar energy and other application fields with high anti-corrosion requirements.

Stainless steel color coated plate performance characteristics:

1. Due to the good corrosion resistance of stainless steel itself, coupled with the fading and corrosion-resistant fluorocarbon coating, the corrosion resistance and fading resistance of stainless steel color-coated plate are further improved, the service life is long, and the comprehensive use cost is low.

2. Stainless steel has good rigid strength, stronger snow load resistance and wind load resistance.

3. Stainless steel is a green and environmentally friendly recycled material, which can be recycled and has high comprehensive cost performance.

Why stainless steel should be painted:

1. Reduce light pollution:

The coating can solve the impact of large-area stainless steel light plates on surrounding aircraft channels and high-rise residences.

2. Solve galvanic corrosion:

The surface of stainless steel contains dust containing other metal elements or attachments of dissimilar metal particles. The contact surface between galvanized steel purlins and stainless steel, in humid air, the condensed water between the two will be connected into a micro-battery (potential difference), which will trigger an electrochemical reaction and accelerate the rust and perforation of the contact point. After the stainless steel is coated with an organic coating, insulation is formed to prevent galvanic corrosion.

3. Prevent chemical corrosion:

In polluted air (such as atmosphere containing a large amount of sulfide, carbon oxide, and nitrogen oxide), when exposed to condensed water, sulfuric acid, nitric acid, and acetic acid liquid spots are formed, which can cause chemical corrosion. Especially on coasts and islands, sodium chloride solution has strong corrosion properties on stainless steel. The annual corrosion rate of austenite in brine is at least 0.05-0.5mm, and there is a tendency to pore corrosion and stress corrosion cracking. After stainless steel is coated, it can isolate the contact between the corrosive medium and the surface of the steel plate.

4. Reflect the individuality of the building:

The color of the roof and wall can be customized according to the user's corporate culture, and the exclusive color of the enterprise can fully display the style of the enterprise.

Processing steps of colored stainless steel plate:

1. Degreasing activation:

First, use stainless steel degreasing activation solution to degrease and activate the KTV stainless steel door, and then rinse it with water.

2. Passivation treatment:

After cleaning the door, passivate the door with stainless steel passivation paste or passivation solution for a period of time, from half an hour to more than two hours.

3. Alkaline water rinse:

After passivation is complete, rinse with alkaline water, rinse and rinse the door with water.

4. Spraying liquid:

After completing the above steps, a stainless steel film is applied to the door to form a transparent dura to prevent contamination such as fingerprints.

Advantages of colored stainless steel plate:

1. A new process can be used on the surface of the colored stainless steel plate called fingerprint-free processing technology. This technology mainly uses nano-layer technology to form an extremely thin and very strong protective layer on the surface of the colored stainless steel plate, because it can avoid people's fingers. Leave fingerprints after touching, so it is also called color stainless steel plate without fingerprints. The fingerprint-free processing process can be processed in color stainless steel mirror plate, brushed plate, frosted plate, etched plate, etc., to obtain a fingerprint-free effect, which can be very good. Enhance the anti-rust function.

2. The moldability of the colored stainless steel plate is strong, which changes the defects of the wooden material installation. As a metal material, it also has the advantages of better flame retardancy, mildew resistance, anti-corrosion, moisture-proof, green environmental protection and so on. And the color is processed by vacuum ion plating., the color layer on the surface is rich and colorful, and it is very firm, especially the brushed board or the frosted board, which has better wear resistance than other surface texture states.

3. The surface patterns of the colored stainless steel plate are three-dimensional and rich. The equipment and processing technology used can etch a three-dimensional pattern with concave and convex feeling, clear texture and tightness on the surface of the colored stainless steel plate. Combined with various colors, it is full of modern fashion trends. The artistic sense activates the atmosphere in the kitchen.

4. The colored stainless steel plate changes the unfirmness of the wooden plate, and is firmer than the wooden material and increases the sink resistance of the product floor.

5. Relatively speaking, materials such as stone and wood are moldy or weathered when exposed to water for a long time in the kitchen, and other metal materials are not suitable for kitchen decoration in moisture, so colored stainless steel metal is far more suitable than other materials. Cabinet decoration, but this metal material also has good or bad quality. Generally, stainless steel plates made of 201 and 304 are commonly used, but 304 plates will have stronger rust resistance.

Shandong Xirui Metal Materials Co., Ltd. always adheres to the tenet of customer first, integrity first, mutual benefit and win-win, constantly pursues more customer quality, and welcomes new and old customers to visit.

Aluminum Magnesium Manganese Roof Panel

Light weight The density of aluminum is 2.73G/M3, only 1/3 of steel

Fluorocarbon Aluminum Magnesium Manganese 25-430

Light weight The density of aluminum is 2.73G/M3, only 1/3 of steel

65-400 Aluminum Magnesium Manganese

Light weight The density of aluminum is 2.73G/M3, only 1/3 of steel

65-430 Aluminum Magnesium Manganese

It has many advantages such as corrosion resistance, beauty, light weight, high strength, easy processing and molding. It is widely used in airport terminals, aircraft maintenance depots, stations and large transportation hubs, conference and exhibition centers, stadiums, exhibition halls, large public entertainment facilities, public service buildings, large shopping malls, commercial facilities, civil residences and other buildings. The 270 ° occlusion process of this roof panel is made by automatic professional operation of the automatic occlusion machine to bite the bilateral single support, and the package buckling method formed by the buckling edge and the support ingeniously solves the physical displacement caused by thermal expansion and contraction. This advantage is reflected in the fact that the lengthwise long-span roofing system does not deform due to internal and external forces. At the same time, the complete and complete supply of accessories for this roofing system can meet the requirements of various building forms.

Leave A Message