Color steel plate

Category:

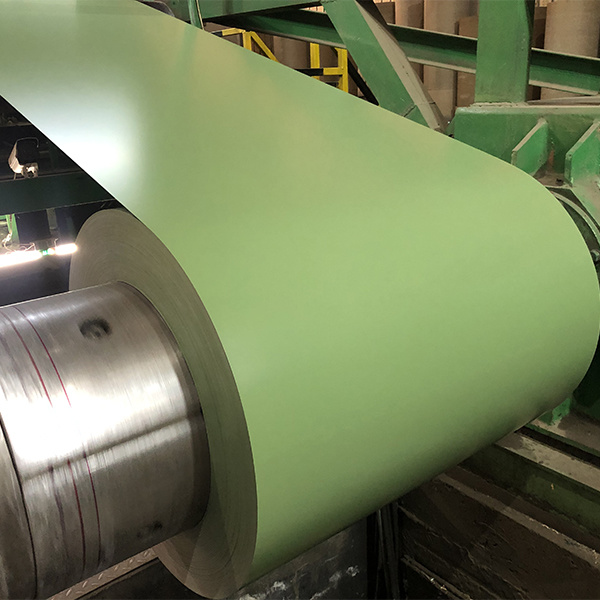

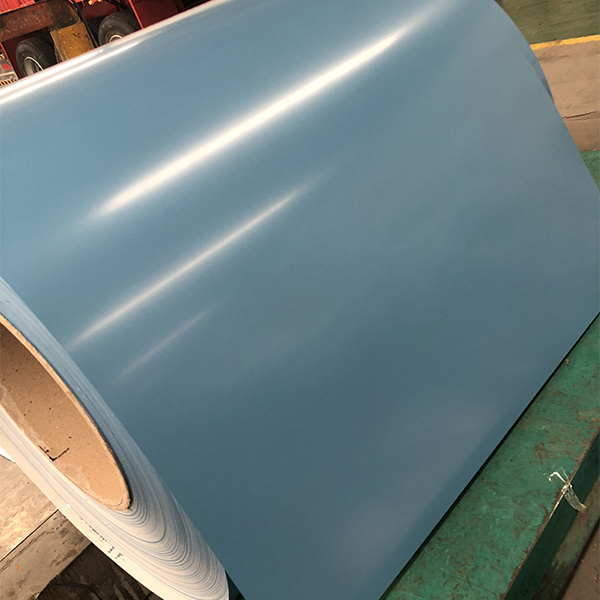

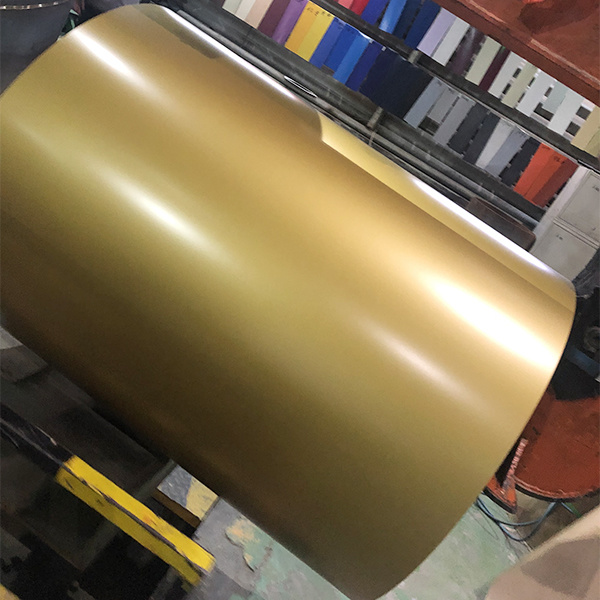

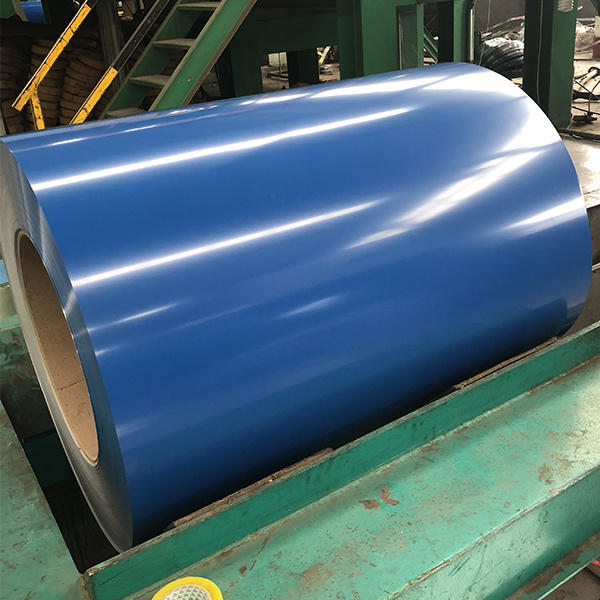

The color-coated steel plate is based on cold-rolled strip and galvanized strip (electro-galvanized and hot-dip galvanized) as the substrate on a continuous unit, and after surface pretreatment (degreasing and chemical treatment), it is coated with one or more layers by the method of roller coating. The liquid paint is used to transform the plate obtained by baking and cooling.

Keywords:

E-mail:

Details

The color-coated steel plate is based on cold-rolled strip and galvanized strip (electro-galvanized and hot-dip galvanized) as the substrate on a continuous unit, and after surface pretreatment (degreasing and chemical treatment), it is coated with one or more layers by the method of roller coating. The liquid paint is used to transform the plate obtained by baking and cooling.

Since the coating can have a variety of different colors, it is customary to call the coated steel plate a color coated steel plate. And because the coating is carried out before the steel plate is formed, it is called a pre-coated steel plate in foreign countries.

Color-coated steel plate is an organic coating applied to the surface of steel. It has the advantages of beautiful appearance, bright color, high strength, good corrosion resistance, convenient processing and molding, and can also reduce costs and pollution for users.

Aluminum Magnesium Manganese Roof Panel

Light weight The density of aluminum is 2.73G/M3, only 1/3 of steel

Fluorocarbon Aluminum Magnesium Manganese 25-430

Light weight The density of aluminum is 2.73G/M3, only 1/3 of steel

65-400 Aluminum Magnesium Manganese

Light weight The density of aluminum is 2.73G/M3, only 1/3 of steel

65-430 Aluminum Magnesium Manganese

It has many advantages such as corrosion resistance, beauty, light weight, high strength, easy processing and molding. It is widely used in airport terminals, aircraft maintenance depots, stations and large transportation hubs, conference and exhibition centers, stadiums, exhibition halls, large public entertainment facilities, public service buildings, large shopping malls, commercial facilities, civil residences and other buildings. The 270 ° occlusion process of this roof panel is made by automatic professional operation of the automatic occlusion machine to bite the bilateral single support, and the package buckling method formed by the buckling edge and the support ingeniously solves the physical displacement caused by thermal expansion and contraction. This advantage is reflected in the fact that the lengthwise long-span roofing system does not deform due to internal and external forces. At the same time, the complete and complete supply of accessories for this roofing system can meet the requirements of various building forms.

Leave A Message