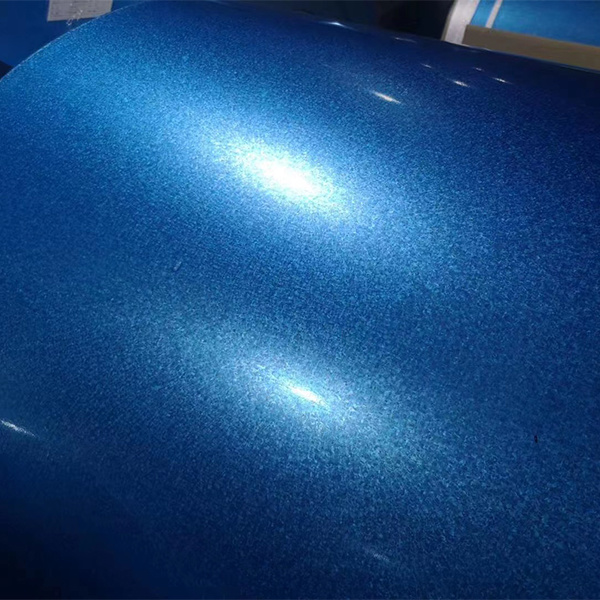

aluminized zinc sheet

Category:

1. Heat reflectivity: The heat reflectivity of galvanized steel sheet is very high, twice that of galvanized steel sheet, and people often use it as a heat insulation material.

Keywords:

E-mail:

Details

Features:

1. Heat reflectivity: The heat reflectivity of galvanized steel sheet is very high, twice that of galvanized steel sheet, and people often use it as a heat insulation material.

2. Heat resistance: Aluminum-zinc alloy steel plate has good heat resistance and can withstand high temperatures of more than 300 degrees Celsius. It is very similar to the high temperature oxidation resistance of aluminized steel plate and is often used in chimney pipes, ovens, illuminators and daylight shades. Corrosion resistance: The corrosion resistance of aluminized zinc steel coils is mainly due to the protective function of aluminum and aluminum. When zinc is worn, aluminum forms a layer of dense alumina, preventing further corrosion of the interior by corrosion-resistant substances.

3. Economy: Because the density of 55% AL-Zn is smaller than that of Zn, the area of aluminized steel sheet is more than 3% larger than that of galvanized steel sheet under the condition of the same weight and the same thickness of the gold plating layer.

4. It has excellent adhesion between the easy-to-paint aluminized galvanized sheet and the paint, and can be painted without pretreatment and weathering treatment. The coating adhesion of the gold-plated layer of the aluminized galvanized steel sheet is relatively good, so it can also be directly applied to the advertising board and general board without pretreatment such as Weathering.

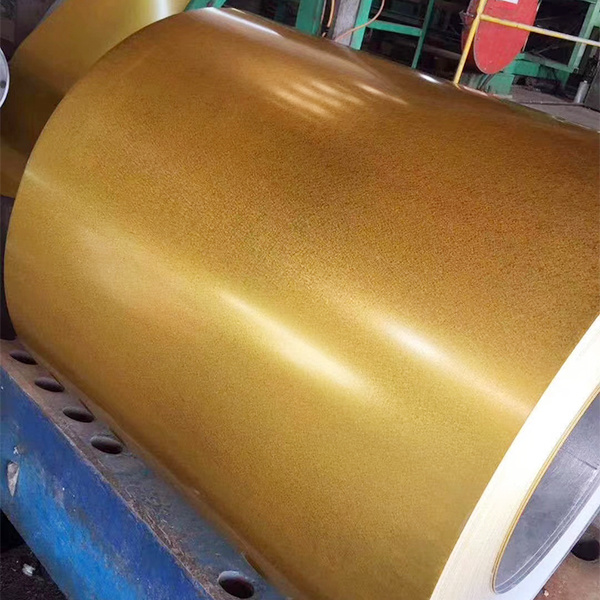

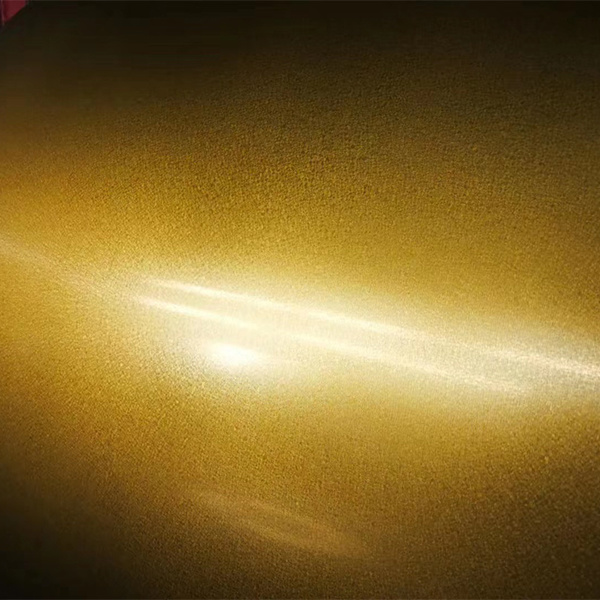

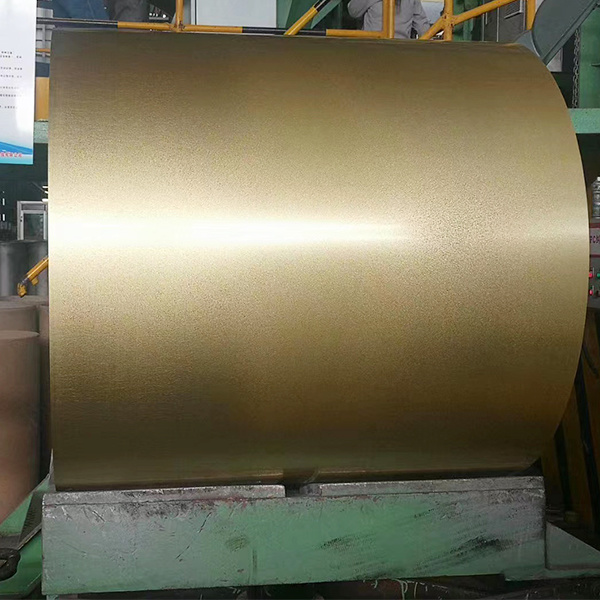

5. Aluminized zinc steel plate has a gorgeous silver-white surface.

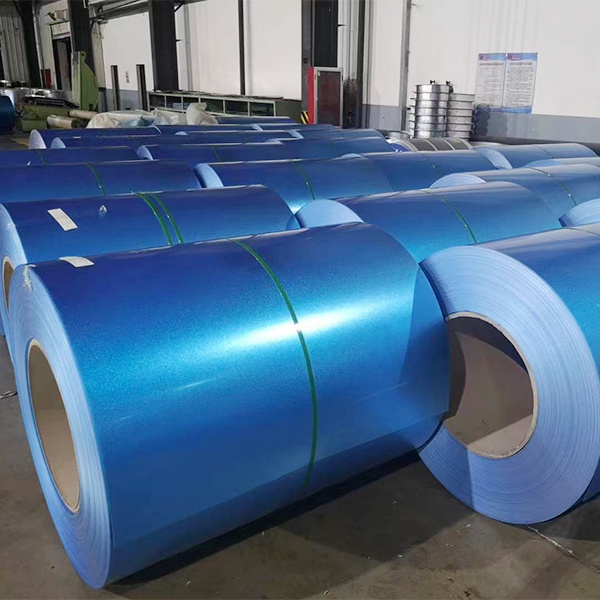

6. Galvanized steel sheet and galvanized steel sheet have similar processing performance and spraying performance.

Aluminum Magnesium Manganese Roof Panel

Light weight The density of aluminum is 2.73G/M3, only 1/3 of steel

Fluorocarbon Aluminum Magnesium Manganese 25-430

Light weight The density of aluminum is 2.73G/M3, only 1/3 of steel

65-400 Aluminum Magnesium Manganese

Light weight The density of aluminum is 2.73G/M3, only 1/3 of steel

65-430 Aluminum Magnesium Manganese

It has many advantages such as corrosion resistance, beauty, light weight, high strength, easy processing and molding. It is widely used in airport terminals, aircraft maintenance depots, stations and large transportation hubs, conference and exhibition centers, stadiums, exhibition halls, large public entertainment facilities, public service buildings, large shopping malls, commercial facilities, civil residences and other buildings. The 270 ° occlusion process of this roof panel is made by automatic professional operation of the automatic occlusion machine to bite the bilateral single support, and the package buckling method formed by the buckling edge and the support ingeniously solves the physical displacement caused by thermal expansion and contraction. This advantage is reflected in the fact that the lengthwise long-span roofing system does not deform due to internal and external forces. At the same time, the complete and complete supply of accessories for this roofing system can meet the requirements of various building forms.

Leave A Message