04

2020

-

04

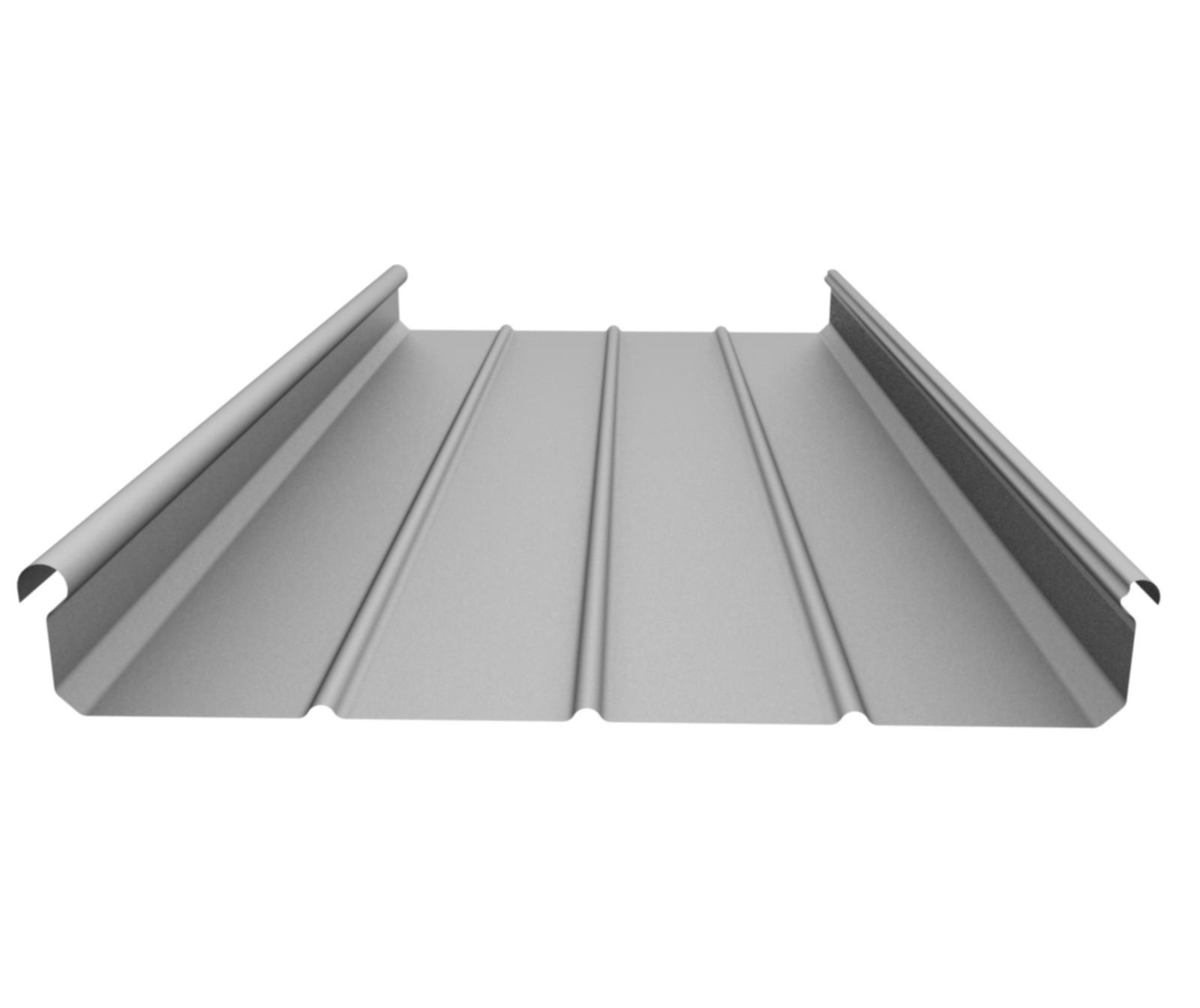

Comparison of application advantages of fluorocarbon-coated aluminum-magnesium-manganese plate compared with color steel plate

Fluorocarbon-coated aluminum-magnesium-manganese panel is a high-quality roofing material that has attracted more and more attention from the market. It is gradually replacing color steel tiles and becoming one of the main players in the market with lightning speed. Why do customers choose fluorocarbon-coated aluminum-magnesium-manganese panels one after another?

Durability comparison: Fluorocarbon-coated aluminum-magnesium-manganese plate can form an alumina film with the atmosphere to prevent further corrosion. It is generally used in civil buildings with 15-20 years of coating quality assurance, and the architectural design service life is more than 50 years. Usually, the product warranty period is 25 years; color steel plate is easily corroded and rusted under humid air and rain and snow erosion, especially the parts of rivets and seams, and leads to fracture accidents.

Weight comparison: Fluorocarbon-coated aluminum-magnesium-manganese plate is lighter (density is 2730kg/m3); color steel plate is heavier (density is 7850kg/m3).

Strength and stiffness comparison: Fluorocarbon-coated aluminum-magnesium-manganese plate has magnesium and manganese content, so it has certain strength and stiffness. However, the internal stress, hardening and strength of the aluminum alloy plate have no obvious yield point, which is not as good as that of the color steel plate; the strength and stiffness of the color steel plate are better, and it is not easy to deform.

Appearance control: Fluorocarbon-coated aluminum-magnesium-manganese plates can be divided into non-painted paints such as hammering, embossing, and pre-passivation alumina surface treatment, as well as PVDF, SMP, PE and other paints; color steel plates can be divided into hot-dip galvanized steel plates and PVDF, SMP, PE, HDP and other paints.

Forming: Fluorocarbon-coated aluminum-magnesium-manganese plate has good weldability, high plasticity, high strength and ductility of aluminum alloy in low temperature environment, and good low temperature processing performance; color steel plate is prone to cold brittleness at low temperature.

Cost-effectiveness: Fluorocarbon-coated aluminum-magnesium-manganese plate is more cost-effective, light in weight, waterproof, easy to bend, and has a good three-dimensional feel; color steel plate has lower cost performance, heavier weight, slightly poor water resistance, and strong steel. Arc is slightly worse, and the artistic effect is not good.

MORE NEWS